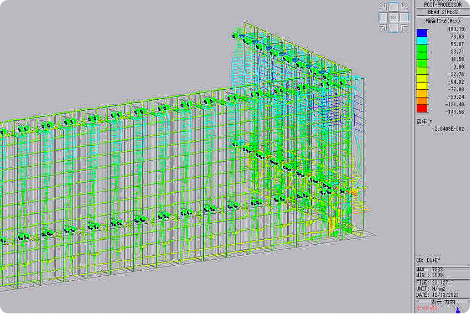

Building information modeling, or BIM, plays an important role in leading-edge building design approaches. Revolving mainly around the use of 3D models, BIM enables all-inclusive management of building design, construction and management, and improves collaborative synergy and general efficiency. Centralized management of data optimizes everything from design through to construction, installation and maintenance, thus improving end quality and sustainability for the building in question.