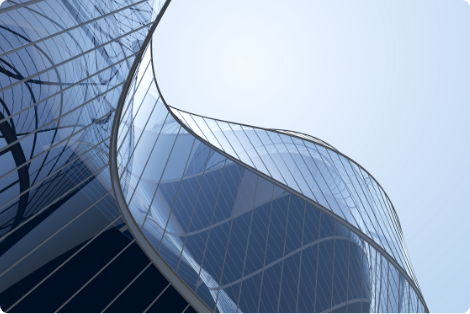

Metal point glazing, or MPG, is the affixing of glass panels at edge and corner joining sections by sandwiching them between metal fittings on the inside and outside. It uses fewer support fittings compared with sash-based supports which pass through the glass, resulting in clear and almost perfectly smooth glass facades.